Examples of housing systems for poultry

When selecting an appropriate housing system for layers it is important to determine the needs of both the chickens and the people operating. A system that is

labor efficient, reasonable in investment and easy to manage can be designed after considering the factors that affect the comfort, protection, efficiency and production of layers.

There are five major systems used in housing of layers:

Semi-intensive, deep litter, slatted or wire floor, a combination of slatted and deep litter; and cage or battery system.

Semi-intensive poultry housing systems

Semi-intensive systems are commonly used by small scale producers and are characterized by having one or more pens in which the birds can forage on natural vegetation and insects to supplement the feed supplied. Provide at least two runs for alternating use to avoid build up of disease and parasites. Each run should allow at least 10 to 15m2 per hen and be fenced. A free-range allowing 40 to 80m2 per hen is required where the hens are expected to obtain a substantial part of their diet by foraging.

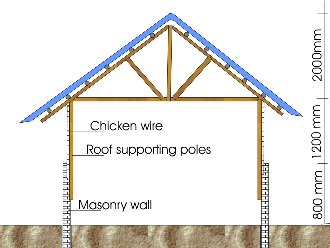

Small simple poultry house

A small, simple house, which allows 0.3 to 0.4m2 per bird, and which has thatched roof, a littered earth floor and slatted or chicken wire walls on at least three sides will provide protection from rough weather, from predators at night and offer shade in the day time. The shelter should be large enough to enter to collect eggs and be equipped with nest boxes, feeders, drinkers and perches. For convenience the house should be situated so that access to each of the runs can be provided with small outlet doors.

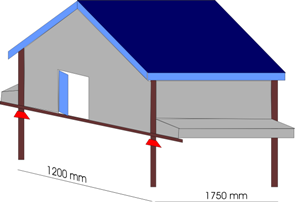

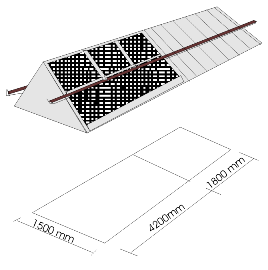

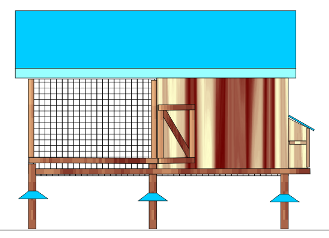

Here is an example of a shelter for roosting and laying, which can be used in combination with daytime foraging by the hens. The legs of this structure have rat guards and ant protection and may be equipped with skids or wheels to make the whole unit easily movable between runs. Feed and water are provided in troughs outside the house.

This system is low in cost, but growth of the birds and egg production are likely to be less than with systems offering closer confinement and better feed. Losses may be encountered by birds of prey and from failure to find eggs laid in bushy areas. The poultry run requires a considerable amount of fencing.

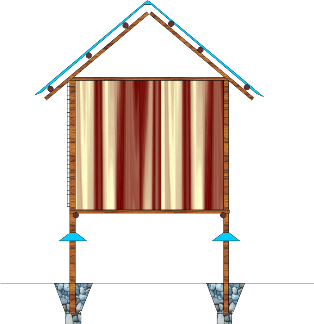

Fold unit

A fold unit is a house and run combined, having part of it covered with chicken wire and the remainder with solid walls. The unit should allow 0.5m2 per bird and must be moved each day over an area of grassland. A unit 6 by 1.5m will take 16 to 18 birds. For larger flocks several such units are required.

Portable units are generally more expensive than permanent houses and may decay quickly because of contact with the ground. Hens have reasonable protection against bird of prey and rough weather and parasites if the unit is not returned to the same area within 30 days.

A yard deeply littered with straw and allowing only 0.4 to 0.7m2 per bird provide for an outdoor exercise area in areas where grassland is limited. This system is similar to the deep litter system but it requires more space, more litter for the yard and fresh green food has to be carried to the birds.

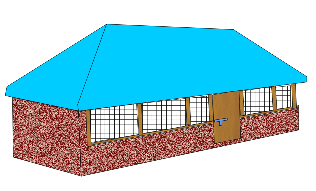

Deep Litter System

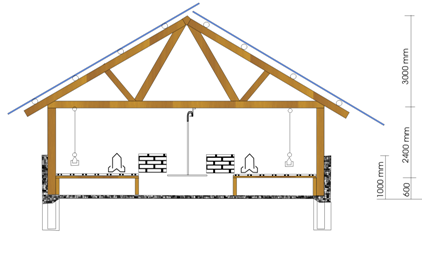

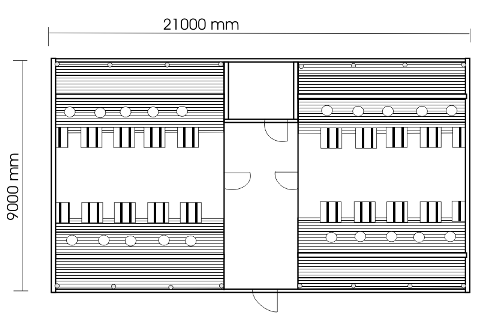

Here is an example of a deep litter house for 130 layers (or 350 broilers). The birds are confined and well protected. With low masonry walls set on a concrete floor and wire mesh on the upper part of the walls, the building excludes rats and birds.

Rough cast and other materials can be used for the walls. The house can be designed up to 9m in width and any length that is needed. The density of birds is approximately 4 to 5 birds/m2 of floor area.

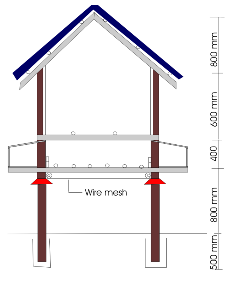

Slatted or wire floor housing system

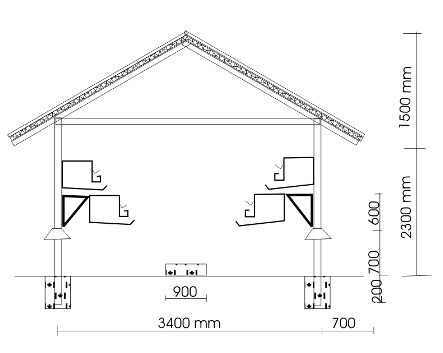

Wire mesh or wooden slatted floors are used instead of deep litter. A slatted floor house for 50 layers is shown below. The house can be built on treated wooden piers 0.8 to 1m above the ground. Ventilation and manure removal are both facilitated and bird density can be 6 to 8 per m2.

A thatch roof or corrugated iron roof may be used with the eaves about 1.5m above the floor. If the latter is used, some insulation under the roof is required.

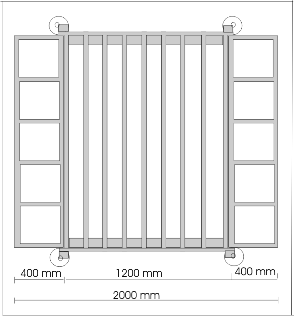

The feed troughs should be equipped with hinged covers and rat guards should be installed at the top of each pier. The width of this type of building should be limited to about 2m to allow easy removal of manure and adequate wall space for feed and nests.

The building should be oriented east and west and may be of any length. However, if it is more than 5m long, nests will need to be put on the sides and all remaining wall space on either side used for feeders in order to allow the required 100mm/bird.

If using a slatted floor made sufficiently strong for a person to walk on, then a wider building is feasible as feeders can be placed completely inside where the chickens have access to both sides of the trough. The floor is sectioned for easy removal during cleaning out of manure.

This type of houses is cooler than other types, but the building cost is high and management is more complicated.

Combination of slatted floor and deep litter

A combination deep litter, slatted floor house, offers some advantage over simple deep litter house, but with some increase in investment.

Approximately ½ of the floor area is covered with small gum pole slats or with wire mesh. This area is raised above the concrete floor 0.5m or more so that cleaning under the slatted portion may be done from the outside. Waterers and feeders are placed on the slatted area. This type of house is limited in width to 3 to 4m so that feeders and waterers can be handled from the litter area and manure beneath the slatted area can be easily removed from the outside without moving the slats or disturbing the birds. Although this system entails added expenses for materials and labor to install the slats, the bird density can be increased to 5 to 7 per m2, so there is little difference in the cost per bird.

This system saves on litter, increases litter life, reduces contact between birds and manure, and allows manure removal without disturbing the hens. Ventilation is improved due to the slatted floor. Perhaps the biggest disadvantage is the limited width for convenient operation and the need for some litter.

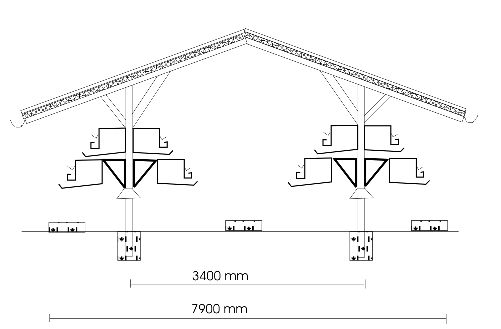

In medium to large scale houses of this type the slatted floor must be made removable in sections and at least part of it made strong to walk on. An increased building cost and a more complicated management will result, however. The house shown has slats over 2/3 of the floor area. This is generally considered maximum for this type of house and allows for stocking density of up to 8 birds per m2. Automatic tube feeders are placed on the slatted floor. One such feeder, with a bottom diameter of 0.6m can serve for 60 to 75 birds, depending on size of breed.

The water troughs are suspended from the ceiling. The nest boxes are doubled by arranging them back to back and have one end resting on the slatted floor and the other suspended from the ceiling. Egg collection can be facilitated by use of a trolley, which is supported on a rail just below the ceiling. Cleaning out between batches can be done by a tractor shovel, if all furnishings and part of the end walls are made removable.

Cage or battery systems

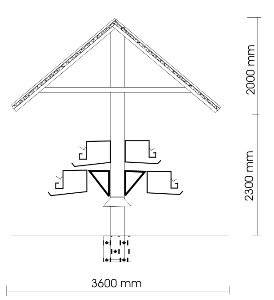

There are much simpler cage systems that may work very well for commercial growers in Kenya. These consist of rows of stairs-step cages in long narrow shelters. The thatch roof or insulated metal roof shelter can be completely open on the sides with perhaps some hessian curtains in areas where cold winds are experienced. The building should be oriented east and west and designed to provide shade for the cages near the ends.

A 3.4 metre length will allow for four cages without overlap and alley of about 0.9m. While a concrete floor makes cleaning easy, smooth hard soil is less expensive and quite satisfactory. A little loose sand or other litter spread on the soil before the manure collects will make manure removal easier. The building posts should be treated with wood preservative and sturdy enough to support the cages. Rat guard should be installed on the posts at a height of 0.8 to 1m. A central alley, raised 20cm and cast of concrete is easily cleaned and keeps manure from encroaching on the work area. Feeding and egg collecting are easily done by hand or with an automatic system. It is important that the watering trough be carefully adjusted so that all birds receive water. The simplest method of supplying water automatically or by hand at one end is to slope the entire building and row of cages 10mm/3m of length.

The trough can then be attached parallel with the cages. Water must run the total length of the trough and it is inevitable that some will be wasted. Consequently a good water supply is essential.

Even though feed is distributed by hand, feed stores should be built convenient to each building to reduce carrying to a minimum. Eggs can be collected directly on to the flats that are stacked on a cart which is pushed down the alley. The cart can be made self-guiding by means of side rollers that follow along the edge of the feed troughs or the raised central alley.